Materials are the key to the growth and development of 3D printing technology. As the technology is adopted by a larger section of the industry the need to materials will only increase and it will be the factor determining the proliferation of the 3D printing technology.

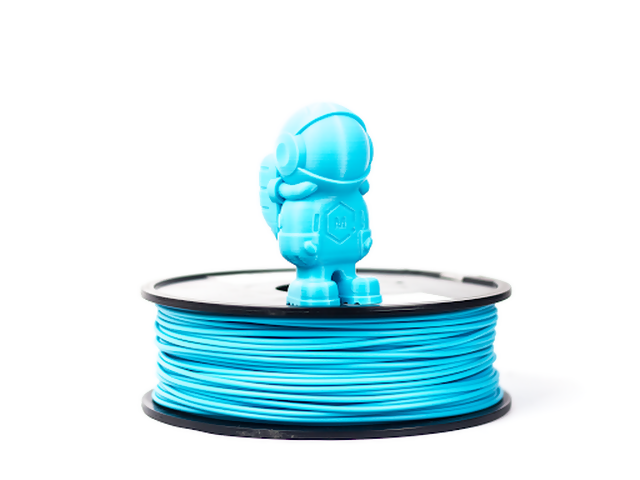

Here, through this article we talk about the popular filaments (materials) available in FDM 3D printing technology.

PLA 3D Printing Filament

Polylactic Acid (PLA) is one of the most commonly used 3D printing filament mostly by enthusiasts, hobbyists and students. It is made from plant-based starches and so it is a bio-degradable material. Moreover it is easy to print with, it is affordable and easy post-process. All these characteristics make PLA the most favoured choice among users to make prototypes.

But PLA is not suitable for end-use applications as it does not offer enough mechanical strength. This fact limits its use to prototypes, educational models, gifting, cosplay & props and architecture. But now-a-days it is gaining immense popularity for the manufacture of prosthetics due to its apparent benefits.

However, PLA is not suitable for parts with continuous exposure to heat as it has low heat resistance compared to other filaments.

ABS 3D Printing Filament

Acrylonitrile butadiene styrene (ABS) is a popular material used in industrial applications. A lot of everyday use items are actually made from ABS material. Products like wall sockets, kitchen appliance casings, computer keyboards, Lego bricks, and other casings are made by injection molding of ABS.

Due to these wide usage the material is easily accepted in industries and hence a lot of industries use 3D printed ABS products as well.

ABS is a versatile thermoplastic. It has high temperature resistance, excellent mechanical properties & impact resistance, offers a high-degree of surface quality and even exhibits good electrical insulation properties.

These properties help ABS to be one of the world’s most widely used 3D printing filament in FDM 3D printing.

ABS 3D printing filament can also be post-processed in various ways and can be turned into a glossy product which expands its application base. However, 3D printing of ABS releases toxic fumes which can lead to breathing problems and so the printing should be carried out in a well-ventilated environment.

ABS 3D printing filament is prone to warping and cracking at edges, so a heat bed is essential to print with ABS. This helps in keeping the printed layer hot avoiding the temperature difference thereby having a stable print experience.

PET 3D Printing Filament

PET is popularly used in mineral water bottles and is a very well-known material. PET is a transparent & strong and highly durable filament. PET 3D printing filament is popularly used in the PETG for while 3D printing. This is achieved by addition of glycol. Glycol helps the PET material become brittle and eliminates the hazing effect seen during printing. This helps in achieving a comfortable grip on the product but this also renders it susceptible to damage due to UV light.

Similarly, PET is combined with various other chemicals to modify its properties and produce a strong material which suits the specific application.

HIPS & PVA 3D Printing Filament

High Impact Polystyrene (HIPS) & Polyvinyl Alcohol (PVA) 3D printing filaments, both, are widely used as support materials for 3D printing. Both these filaments are soluble in nature and hence they make a perfect support material. HIPS dissolves in a chemical called as Limonene while PVA is a water soluble filament.

HIPS can also be used as a separate 3D printing filament as it exhibits high impact resistance and good durability. But mostly it is used only as a support material in combination with ABS.

PVA also can be used as an individual 3D printing material but it also is used in combination with PLA as a support material.

Flexible 3D Printing Filament

ThermoPlastic Elastomer (TPE) & ThermoPlastic Polyurethane (TPU) are two elastomers which are used as flexible 3D printing filaments.

Both, TPE & TPU are quite similar to each other but TPU is more rigid than TPE. These elastomers offer high elasticity and flexibility like rubber. The printed part can be deformed by twisting & bending but it returns to its original shape once the force is removed.

Both these filaments are quite difficult to print with and so the print speeds are kept extremely low.

PEEK/PAEK 3D Printing Filament

PEEK (PolyEtherEtherKetone), PolyArylEtherKetone (PAEK) & PEKK (PolyEtherKetoneKetone) are organic thermoplastic polymers which exhibits some of the best properties than any other thermoplastic material. All three materials have similar properties with each material being slightly different to improve certain property. It has unique properties which are aspired by prominent industries like Automotive, Aerospace, Oil and Gas & medical.

Due to their superior properties, these 3D printing filaments have the potential to replace metal prototypes in a variety of applications.

3D printing with all these materials various according to different factors. Every filament requires different operating temperatures, different build plate surface and build plate temperature, some of them require fully enclosed printing while some require an altogether different nozzle. All this is not available in a single 3D printer and so users may require help form established 3D printing service bureaus

Service bureaus have multiple 3D printers which suit the particular material and so they are in a good position to fulfil the customers requirements.